LEO's LIGHTING

About Us

Quality Assurance

IN THE MANUFACTURING PROCESS

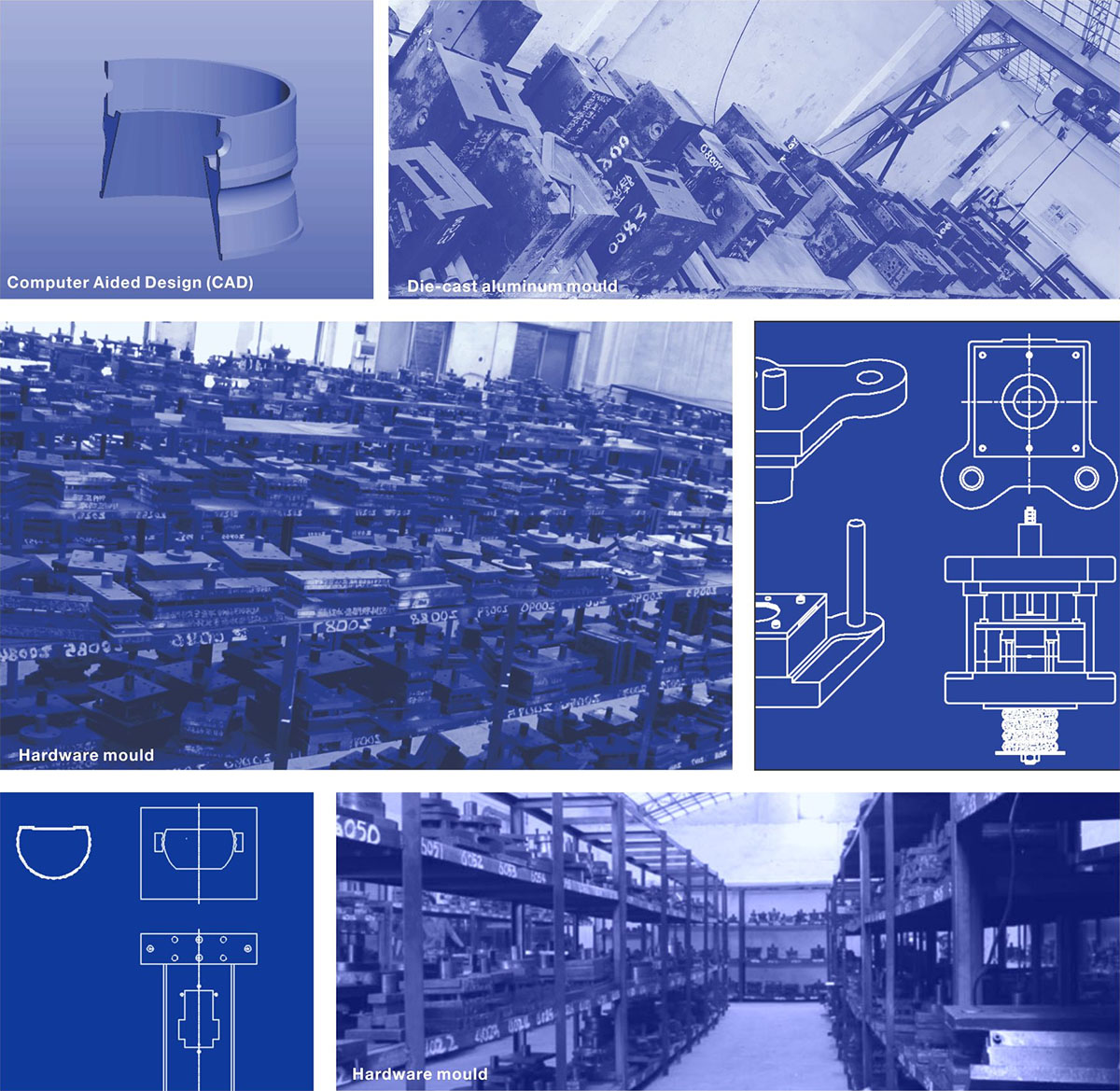

We persist in independent design and development, each workpiece is designed by our professional design team, then the whole light fixture is developed by our R&D department. To avoid or reduce the process of CNC machining in the later stage and ensure the quality consistency of each batch of products, we have chosen the way of production by mold, even wth higher initial investment, all workpieces are mass-produced using molds. Meanwell, the molds required for producing lighting fixtures are all independently designed and developed by our company to ensure controllable quality and reduce overall production

costs while reducing errors.

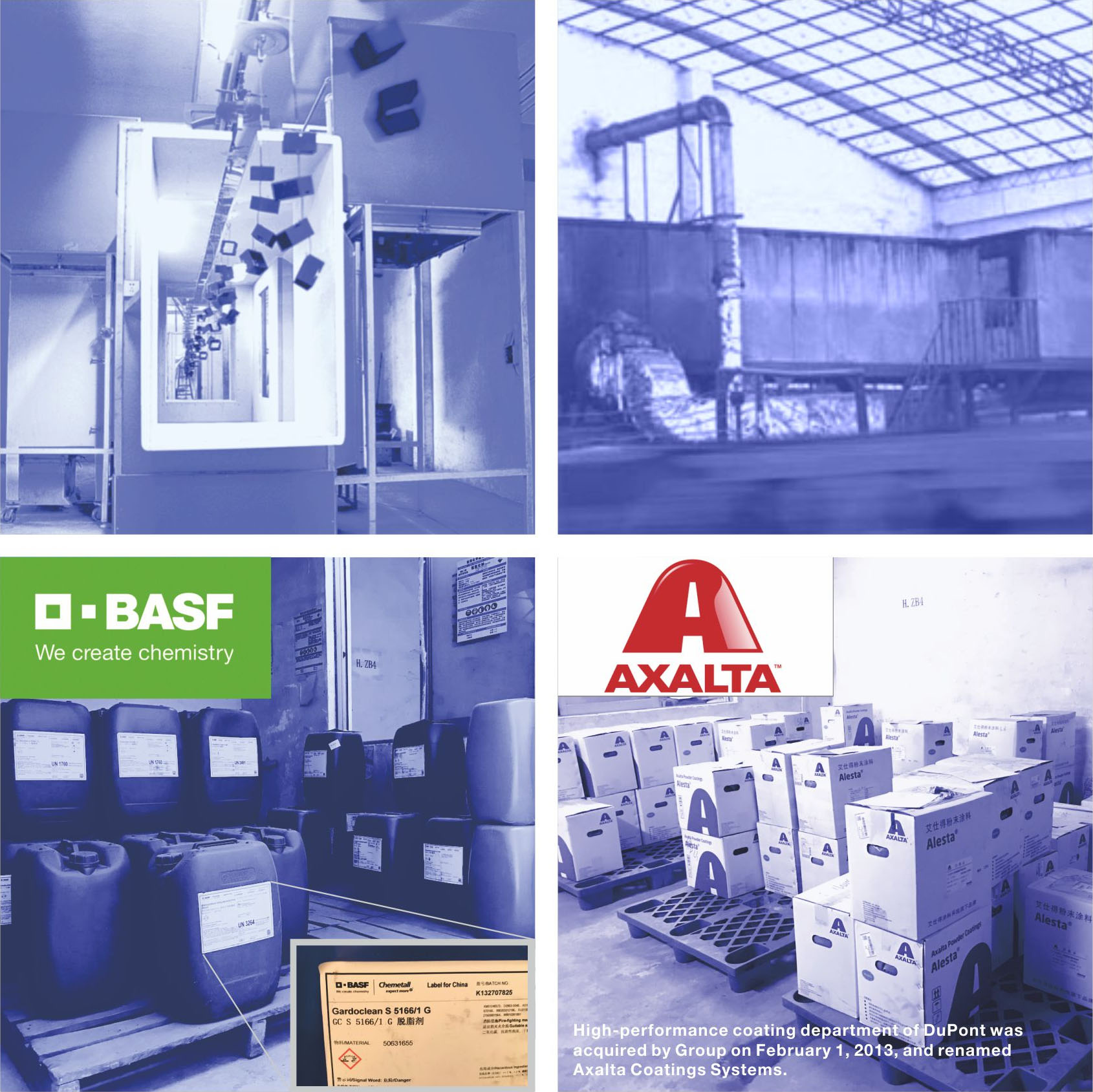

Quality assurance in appearance: We have our own powder coating line, the process of painting for all workpiece is finished in our factory. We use BASF chemical cleaning for pre-treatment, and use DuPont (Acquired by Axalta) outdoor powder for painting on surface. Therefore, we can provide 5-year warranty service on appearance.

Banner title, click to edit.

In the hardware workshop, painting workshop and

assembly workshops, we have quality management

specialists to control the quality before, during, and

after production.

Banner title, click to edit.

Before production:

For each model in each order, we will arrange to make first piece in each workshop, the quality controller during production will inspection the first piece according to the established inspection standards and issue an inspection report. After confirming that the first piece is OK, employees can start mass production of this workpiece.

During production:

Quality control will conduct regular inspections during production and issue inspection reports. For outdoor lamps, we make IP testing for both semi-finished products and finished products to ensure the waterproofing function of the assembled lighting

fixtures.

Banner title, click to edit.

After production:

When the production in each workshop is finished, quality management specialists wil make inspection to make sure the quality of semi-products. For the

quality control of finished products,when the products are finished in assembly workshop, quality management specialists will make inspection according to the established inspection standards and issue an inspection report, to ensure the quality of finished products. For the quality assurance system,we provide 3 years warranty for the whole fitting.

Banner title, click to edit.

1) We welcome customers to inspect the goods at the factory and form an inspection report, we can only arrange for shipment after get customer’s approval.

Banner title, click to edit.

Banner title, click to edit.